Welcome back to Cnuteneering, where the possible is made more difficult by bone headed ignorance, overenthusiasm and pointy metal things being brought together.

You may want to refresh your memory on the project in:

Design goals:

Fast as possible on offroad; too big to have on roads. I will set a target speed of 50mph.

4 WD.

Must be able to reverse, and brake.

Unbreakable, or as close to.

Must be able to mount GoPro or similar camera on it.

Cheap as possible.

We left the last episode of Cnuteneering with some mucking about with the engine and drive train. The TelePi device was fitted and the non IC drivetrain tested.

So now on to bigger and better things I hope.

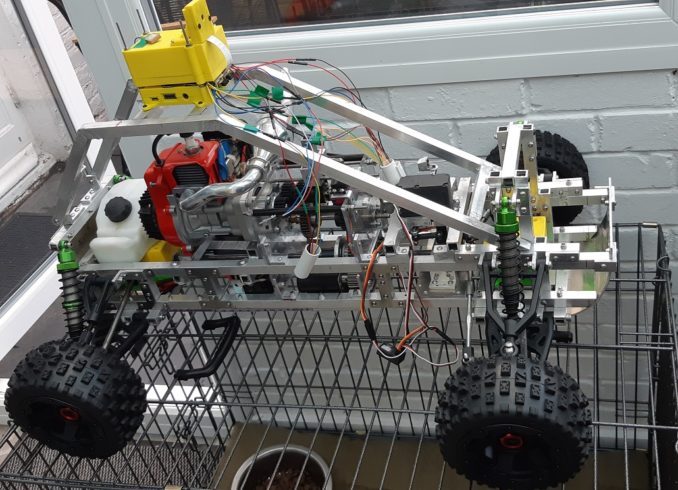

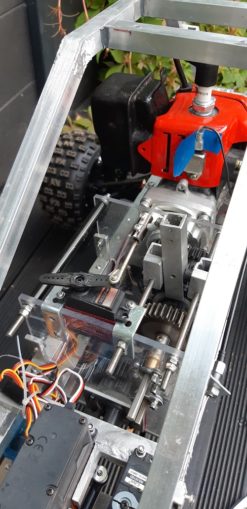

Here is the car before I start mucking about with it

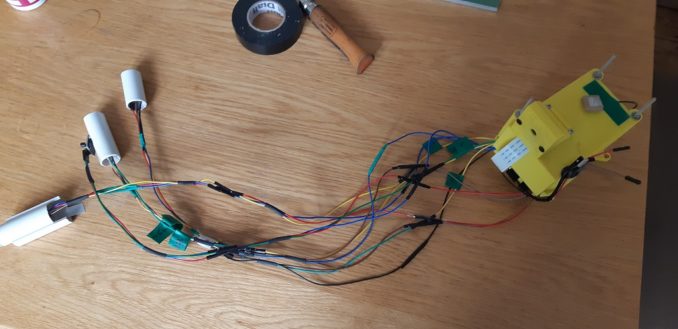

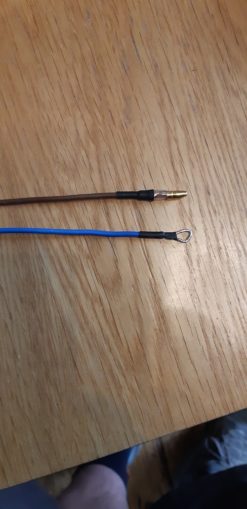

First I have to bring #order to the leads. First, the leads need extending, then they need tidying. The last thing I need is a loose lead going through the gearbox or getting pulled out by any of the moving parts on the car, of which now there are many. I use some shrink sleeving on the cables to good effect:

Then rinse and repeat for each and every sensor. Remember, there are 3 RPM sensors and a temperature sensor so this is quite a lot of faffing. Fortunately it is soldering so I am nicely in my comfort zone of I KNOW HOW TO DO THIS PROPERLY which is a rarity in Cnuteneering.

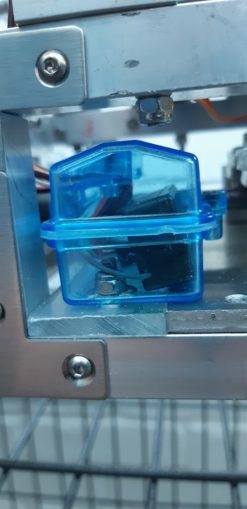

For about a fiver I go a waterproof (not watertight though!) box to put the Rx control gear in. A bit of Perspex to bring it level with the steering yoke mount plate and I get to make use of one of the holes I drilled in the wrong place previously, so I will pretend it was by design and give myself a pat on the back.

It is really tight and fiddly in the front of the car now though

But everything is clipped to the chassis now so it is not going to flop about everywhere when the car starts moving.

And so I trot off to a local area where there is a dirt road, a bloody great drop on one side and bollards the other. I still have no idea how well the brakes work so I try it out in reverse just to see if the motor has enough grunt to shift the car on broken ground, with the engine on and everything attached bar the TelePi.

This is of course, very exciting as it is one of the design goals met, but the real thing I want to test is the Going Forward At Speed.

Not quite the lightning off the starting blocks I was hoping for but it does at least go forwards. There is however a massive bias to the right because I have clearly not adjusted the turnbuckles very well. This is fine, it is just one of those things to work out as I go, a brief 30 seconds with the spanner should sort that out. Apart from the spanner that fits is sat at home.

Apologies for the occasional owl view – the steering controller is hard to use when holding a phone at the same time, so I can’t steer and focus on the car simultaneously.

At about this point the engine started cutting out, even not under load. It would start, run for a 10-15 seconds and then die. At this point I am not sure if it is related to the washer in the clutch problem as per last episode.

I pack up the car, and then notice the butchers bill from the run out.

During testing, one of the drive cups has fallen off and been lost. This is quite bad as finding a replacement will be troublesome, to say the least.

I also appear to have lost a nut off the bottom of the steering knuckle / suspension arm.

I suspect the two may be related. In the meantime I avail myself of the collective wisdom of the puffinry, and Distant Cumbrian and others were very helpful with their diagnosis of why the engine is stopping. I revisited the test site, and was pleasantly surprised to find the missing drive cup.

Car patched up temporarily, I take it out again only for the engine to just keep stopping. By chance a bloke stops by to have a look and sucks his teeth. I am expecting an uninvited critique of my poor workmanship, but he instead advises that I have my fuel / oil mix utterly wrong and there is way too much oil in it. “Sort that out back in your workshop, put a new spark plug in and it’ll fly” he says. “Workshop?” I laugh, and go on to briefly describe my state of the art facilities.

“Bloody hell, all on a workmate!” he exclaims. “When I used to run the dirt bikes I had a whole garage, I used to run my own car mechanic business”.

My faith in the Gods of Cnuteneering was restored. Sadly I had to get back home or I would have tried to get more info out of him, but at least I had wangled an opinion from a master mechanic. #WINNING

Back to Cnut central for yet more tightening of bolts and nuts.

I also ordered some more bits which arrived tout suite

Mindful that when I mixed the fuel last time, it was outside in the rain and cold so I was not really paying much attention to it really. And a bit more oil is a good thing, right? Nope, not at all as it turns out.

Mixing accurately is harder than you think though.

So I waited until dark and then back lit it.

And I changed the spark plug.

No idea if I can clean this off at all but in any case, this amount of filth can not have been helping matters.

I also put the original muffler on the engine too, just in case the shiny race can was causing the problem.

I found a new test site that is much closer and fired up the beast, having already corrected the steering this time.

Midway through testing though, more bits fell off

Running field repairs were made with a bit of bent wire I found on the ground

This breakdown could not be fixed in the field though, shit welding from a shit welder.

The engine still kept cutting out though, so the only thing aside from a new carburettor that I could think of was to remove the engine cut out switch I’d fitted. Finally, the engine idles nicely and for about 2 minutes straight with no stalling.

So that was it, bad fuel mix, dirty spark plug and electrics that were starving the spark plug. A perfect storm of errors to interfere with testing.

Back home and I re-make the leads that fit to the cutout. I double check the wiring and I believe it to be correct but it could be that the wires I am using are just too high impedance as they are so small.

I also fit the aerial sheath. The aerial itself barely protrudes above the top part of the chassis though so this may be a problem with range. I am unsure what happens if I either ground the aerial tip to the chassis or if I just extend it. In any case it ain’t broke right now so I ain’t fixing it.

Searching for bigger test sites reveals lickspittles everywhere

As I am faffing at home I notice the gearbox has gotten tighter for some reason. The two big gears should run freely over the first shaft, only they do not, they bind. This is causing the gearbox to try to have 2 gears engaged at once, which is bad. Further inspection shows that some stupid cnut left a grub screw in one of the freewheeling gears and it has bound to the shaft somehow. FFS! You can’t get the cnuts these days, eh?

Once I took this out the gearbox was much happier, but the other free wheeling gear seems to be binding on the hex bar that holds the gear changer. This is going to need a full heat ray rebuild in order to fix it, so for now I have dosed I in WD40 and a prayer.

The gear change mechanism needs some attention as I have not really been able to try it in motion. I think the spring needs uprating, at the very least but that is a tomorrow problem as I might have to machine a big lump off each freewheeling gear – the selector just does not click in at any speed at the minute.

In the meantime, my attention is elsewhere:

Still waiting for:

Nothing!

Still left to do / think about

End point adjustment for servos and control mechanisms Dumbo RC setup

Siting of RPM counters

Loctite gears in place

Body shell

Sort out freewheeling gears

Pics, vids, words and music © El Cnutador 2021

The Goodnight Vienna Audio file

Audio Player