Welcome back to Cnuteneering, where the possible is made more difficult by bone headed ignorance, overenthusiasm and pointy metal things being brought together.

You may want to refresh your memory on the project in:

Part One.

Part Two.

As ever, the Design goals:

Fast as possible on offroad; too big to have on roads. I will set a target speed of 50mph.

4 WD.

Must be able to reverse, and brake.

Unbreakable, or as close to.

Must be able to mount GoPro or similar camera on it.

Cheap as possible.

And so, we have some pieces arriving from Chy-Na. But the pieces from the USA arrived first so let’s take a look…

This is our starting position, the engine with the internally threaded drive shaft:

This is a picture of all the components in the centrifugal clutch assembly:

In the green square is the shoe holder, in the purple square is the clutch shoes and spring. How strong the spring is determines at what point in RPMs the clutch shoes are thrown out into the clutch bell (orange square bad). The clutch bell is mounted into the clutch carrier, the blue square. Then to hold everything together, the clutch cover is in cyan.

First the shoe holder and shoes go on:

And then finally the rest of the kit.

Just after the clutch kit had been fitted, the wheels arrived. Oooh they’s big!

By comparison to a coffee cup

And my 1/8th scale Vorza

Back to business then. I now have a clutch on the motor, but no pinion gear. I am still waiting for that from Chy-Na. In any case, it is 17T 1.5 Mod. And this is where it gets all bloody engineery.

Gear wheels have many attributes, not just the number of teeth (T) borehole diameter and diameter. There is pitch angle and pressure angle and pitch depth and tooth density and more to cover and and and. Old skool gears are 20DP (Diametrical Pitch), which is the number of teeth that will fit on 1″ of the circumference of the PCD or Pitch Circle Diameter. More modern gears are described as “mod” short for modulus, and they don’t like being connected to Imperial gears.

While the Outside Diameter (OD) of a gear is if you measure between the tips of teeth opposite each other, the PCD is the diameter if the gear had all the teeth sanded off.

If you want gears to mesh properly and not strip each other then the diametrical pitch must match or it will wear the gears quickly and you will get power loss in transmission. However, due to the design of the gearbox, transmission is through the shaft so as long as the gears mesh when they are in contact I can mix and match gear pairs to my liking. Which is handy because the only slipper clutch for my central differential I could find is in fact a geared arrangement.

Which is 20DP.

Just as well then.

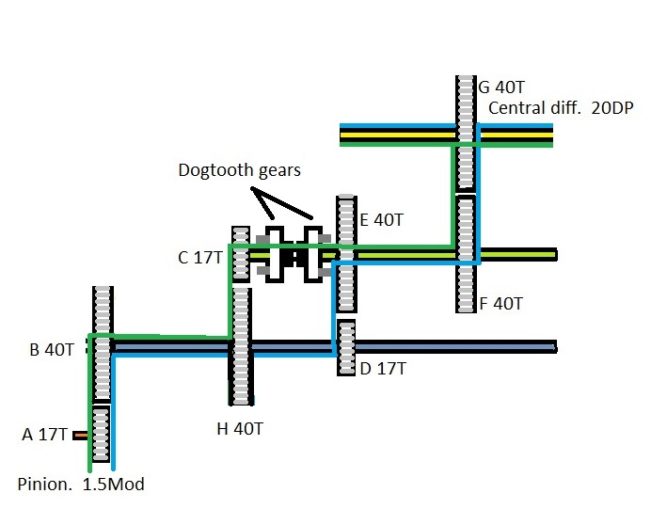

In the above, we have gears A and B needing to be 1.5 Mod, and then C/D/E/H can be whatever, but F must be 20DP as the central diff gear, G, is 20DP.

So let us work out the gearing ratio. In the above the green line goes from 17T –> 40T –> 40T –> 17T. This feeds gear F at the same rotation rate as C, then the final output to wheels through 40T. Similar for the other gear, in blue.

Now I have the wheels I can work out how fast they need to turn in order to hit my 50 KPH aim. The wheels are about 17 cm in diameter, so the circumference of the wheel is pi * d, or 0.534 meters.

Let us recall that 50mph is about 80 KPH, which is 80,000 metres per hour. So in one minute, the car will travel just over 1333 metres if it is going 50mph. If the wheels roll at 2496 RPM, I will get to 50MPH.

I made a handy lookup chart that may be of use, top chart.

I now need to work it back from there to see how the gears interact to go from 8000 from the engine to the target RPM. Low 1st gear should have a lower target RPM than 2nd, high gear where the target is 2496.

I can muck about with RPM inputs and gear sizes and the output RPM is calculated for me. This output RPM is what the driveshaft that runs the length of the car body will rotate at.

Astute non-readers will note that the shafts in the gear label picture above are colour coded in the above table; the pinion gear input has an orange shaft, the central diff shaft is yellow and so on. So gears B and D will rotate at the same speed as the greyish shaft.

Try as I might, I have found no small spline shafts in a small enough diameter to use, far less any hubs (toothless gears) to fit on to them. What I did find however was a D shaft, which is circular with a plane removed from one side (a chord if you are OT), so that viewed from the end it makes a D shape. So I at least have one out of the 2 shafts I need.

All of this faffing about has taken quite some time to find; not only is there a previously unknown lingo to use (bore, DP, Mod etc) but many places are advertising stuff that is out of stock no idea when stocks are replenished. A lot of it is a sad indictment of how Chy-Na has usurped our Western industries – the only mass produced spurs and gears I can see are mainly coming from Chy-Na whereas the UK/US/AU firms seem to be high end made to specification outfits.

Having typed that I know what a hypocritical position that is, but I cannot afford to have a few gears machined to order in the UK and Chy-Naese firms will do it for comparative pennies.

I still cannot finalise the gearbox gearings though as the differentials may not be 1:1 gearing which I will need to compensate for in the main gearbox.

Now that I am stalled on the gearbox for now, I need to be thinking about how I am going to control the gear select, the throttle, how the suspension is going to work and how to arrange the steering. I have rebuilt some busted old rear shocks from my 1/8th scale Vorza which should go nicely on the front of the CnutMobile.

I also need to look at the air intake; what works for a strimmer is likely not going to work for an engine close to dirt and water being thrown around.

So, a small hiatus now as I am still waiting for delivery of:

Pinion gear clutch bell

Polycarbonate sheeting to make a model of the gearbox with Real Gears ™.

Tachometer

Front and rear diff

Thin angle grinder blades

Wheel hubs

Front wheels

Pics, words and music © El Cnutador 2020

The Goodnight Vienna Audio file

Audio Player