Introduction

My main interest in firearms has always been their technology and development, particularly during the 19th century which saw an incredible advance from flintlock, smoothbore muskets to semi and even fully automatic weapons. This fascination gave rise to a series of eight articles that I wrote for Going Postal under the heading ‘Milestones in Nineteenth Century Firearms Development’. In the articles, I briefly mentioned the paper cartridges that were used prior to the development of the self-contained metallic cartridge since when I have continued to research and experiment with paper cartridges for the .577 Enfield rifle musket. This in turn has led to my becoming intrigued by the divergence in approach that I found in their use by the British and Confederate & Union armies during the 1850s and 1860s. While using to all intents and purposes what were identical weapons, why did the British and the Americans use completely different bullets and cartridges in their rifles and what were the respective advantages and disadvantages in their use? Clearly, a bit of experimental archaeology was called for.

The Development of the Enfield Pattern Rifle-Musket 1853-61

During the Crimean War, the British Army had experimented with the newly developed French Minié rifle which fired a revolutionary new thimble-shaped bullet that was to transform battlefield tactics for ever. From now onward no one was safe even 600 yards and more from a highly trained rifleman and digging-in became a matter of self-preservation. Prior to this, only elite soldiers had been trusted to use rifles and by far the majority had been provided with smoothbore muskets that fired a heavy lead ball of approximately .75” diameter and one ounce in weight that were accurate only to around 100 yards. The big disadvantage of using black powder (gunpowder) as a propellant is that when discharged it leaves deposits known as ‘fouling’ within the barrel and these soon build up, become hard in hot weather or due to the barrel heating with continued firing making loading difficult. To compensate for this, the lead balls provided for use in the nominally .75” bores were only .69” diameter but this led to an inevitable loss in accuracy as the ball would rattle down the barrel on being fired and leave the gun in a somewhat haphazard manner depending on which part of the muzzle it last touched as it exited the barrel.

This ‘windage’ between ball and bore can be taken up by wrapping the ball in a cloth ‘patch’ that centres it in the barrel thereby minimising loss of pressure and improving accuracy but while this was acceptable when hunting or target shooting, it was an inappropriate complication in the heat of battle. This problem of bore fouling is compounded when the bore of the firearm is rifled, that is engraved with spiral grooves designed to impart spin to the projectile and hence improve accuracy. Hunting rifles could be loaded with oversize bullets that on being hammered down the barrel would engage the rifling and self-engrave into it but again, this is not acceptable in a battlefield weapon. The flintlock Baker rifle introduced in 1800 fired a leather-patched ball and each rifleman was provided with a small mallet designed to be used when loading into a fouled barrel, however the rifling twist of the Baker rifle was a very lazy 1 in 125 inches so as to minimise the effects of fouling in the grooves and accuracy was poor at ranges beyond 200 yards.

The genius of the Delvigne-Minié bullet was that although of slightly smaller diameter than the bore of the rifle to facilitate loading, due to its hollow base it expanded as the powder charge exploded causing it to engage the rifling and spin as it sped down the barrel. Early Minié balls (all solid bullets are referred to as ‘ball’ ammunition) were provided with iron expander cups fitted into their base recesses so as to ensure expansion of the bullet skirt into the rifling but on occasions, these cups were shot clean through the soft bullet leaving a ring of very difficult to remove lead in the bore that rendered the rifle unusable without an armourer’s attention. Subsequent ammunition incorporated boxwood and eventually fired-clay expander plugs but shortly before the American Civil War it was found that they were unnecessary and bare, lubricated bullets known as ‘Burton Balls’ replaced them in American ammunition.

Experiments with the Minié rifle and critical reports from users at the Crimea led to the development at Enfield of the Pattern 1853 ‘3-band’ infantry rifle with a bore of .577” and three-groove rifling with a twist of 1 in 78 inches. In 1856 a virtually identical but shorter barrelled ‘Sergeants’ ‘2-band’ rifle was produced but this was criticised due to its barrel being prone to damage when fitted with the huge Yataghan sword-bayonet in use at the time. This led to the introduction in 1858 of a heavier barrelled short ‘Navy’ rifle which had five rifling grooves with a faster twist rate of 1 in 48 inches and brass fittings designed to resist corrosion in maritime environments. When this version was found to out perform the earlier three-groove rifles, it led to the introduction of the Pattern 1861 short rifle that was identical apart from having blued steel rather than brass fittings and this is now thought by many to be the ultimate development of the muzzle-loading infantry rifle.

Loading the Enfield Rifle Musket

When I was first introduced to the Enfield rifle, my shooting mentor taught me how to load it using a powder flask and lubricated bullets cast from a special Parker-Hale mould that had a shallower base cavity and were therefore slightly heavier than the more commonly used Burton-type balls. Years later when I sold my reproduction rifle and replaced it with a genuine Pattern 1856 2-band rifle, I decided to investigate how it would have been loaded when used by its original owner who it would appear was a founder member of the Cheshire branch of the Volunteer Rifles, the forerunners of the Territorial Army.

My research revealed that rather than using a powder flask and loose bullets, the infantry at the time were supplied with arsenal produced ammunition in the form of packets of 10 lubricated paper cartridges each containing a measured charge of powder and a bullet together with a supply of percussion caps. I then found that British cartridges had contained something called a ‘Pritchett ball’ which, unlike any muzzle loading bullet I’d ever seen before was plain sided having no grease grooves or scraper rings. Fortunately I chanced upon an article online that detailed the development of the Enfield cartridge through its three iterations from 1853 to the mid 1860s. A further piece of personal good fortune led to my being present when a fellow shooter had a complete disaster when loading his original Enfield with a paper-wrapped Pritchett bullet that he’d cast from a limited edition mould that he had imported at great expense from the USA. My friend cannot have checked the thickness of his patching paper or the resulting diameter of the wrapped bullet before ramming it down the barrel only to have it jam half way down from where no attempt on the part of the assembled shooters could either force it down onto the powder or extract it.

When shooting a muzzle loader, it is essential that the bullet is sitting in the breech on top of the powder with no air gap between them as to fire it in this condition risks bulging or even bursting the barrel due to a spike in pressure, so shooting the bullet out of the barrel was not an option. We made the rifle safe by soaking the powder charge with water via the nipple and the rifle was taken away for expert attention. In the gunsmith’s workshop the solution was to take a length of 15mm copper pipe into the end of which pointed teeth had been filed and then by rotating the pipe in the barrel cut through the soft bullet releasing its centre leaving a lead ring in the bore. After flushing out the powder charge with water it was then possible to cut the lead ring and remove it without damaging the rifle. The upshot for me was that my friend, perhaps wisely, abandoned his use of Pritchett balls and gave me his mould on extended loan to see if I could resolve the problem of how to use them.

Modern rifle musket target shooters have the distinct advantage over front line infantry of the 1850s and 60s in being able to load their rifles with consistency and precision in the absence of bullets whistling around their ears. By far the majority load using separate components and as the use of powder flasks is now frowned upon or forbidden at club ranges, powder charges are brought to the range pre-measured in vials and batches of bullets are pre-weighed, graded and sized so as to ensure maximum accuracy. On the battlefield, the emphasis was on maintaining a high rate of reasonably accurate fire so factory-produced paper cartridges containing a bullet and a pre-measured charge of powder were provided to both simplify and speed up the reloading process.

The 1850s British Enfield Cartridge

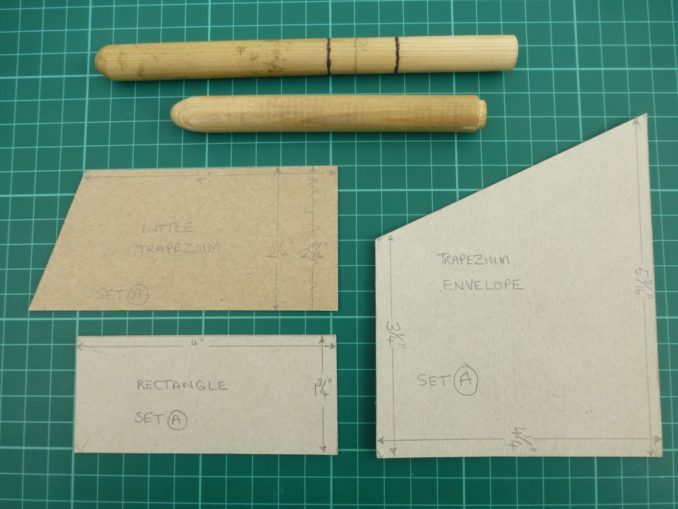

The original 1853 cartridge which I have attempted to recreate used a .568” diameter, 529 grain cylindro-conoidal, pure lead, hollow-based bullet and 68 grains of ‘fine rifle powder’ contained in a paper tube rolled from three separate pieces of paper one end of which was twisted to seal in the powder charge while the other was dipped in lubricant. Following reports of difficulty of loading the cartridges due to the build-up of fouling in the bore in hot climates, a smaller .550” diameter bullet was introduced that contained first a boxwood and subsequently a baked clay expander plug designed to spread the base of the bullet into the rifling at the moment of firing. The paper that wrapped around these bullets was modified by having three cuts that were designed to ensure that the paper jacket dropped away as the bullet exited the muzzle so as to ensure accuracy. While the first pattern cartridge is relatively easy to replicate, the second and third patterns are more complicated to produce and despite claims that they were every bit as accurate as the first pattern, this to date has not been my experience and so, as soldiers at the time were provided with training and the means of making only the first pattern cartridges in the field when arsenal supplies were not available, it is this type upon which I have concentrated.

There is one further consideration; back in the mid 19th century, the military went to great lengths to ensure that only the purest lead was used for the manufacture of Pritchett bullets which were pressure formed from lead wire under enormous hydraulic pressure to ensure uniformity of manufacture and hence accuracy in use. Modern shooters seldom have access to such machinery and have to make do with melting lead often of indeterminate purity casting their bullets in proprietary moulds. Casting large bullets requires careful attention to detail as both the lead and the mould must be at the correct temperature and the molten lead must be poured into the mould at just the right speed to ensure that the cavity is completely filled. Serious competition shooters weigh their cast bullets rejecting any that fall outside set acceptance tolerances and run them through sizing dies to ensure they are all of a consistent diameter.

The first pattern cartridge is made from three separate pieces of paper, the inner two which form the powder container being made from heavier paper of approximately 45 grams/metre2 (gsm) and the outer one that wraps the bullet from very thin but strong ‘onionskin’ type paper of only 32 gsm. Here we encounter another problem as the 100% cotton rag onionskin paper that in the days of typewritten documents was used as copy paper and could be found in any office is no longer manufactured. The last batch I bought came from the USA and cost £80 plus carriage for a one ream box of 20% cotton fibre paper. When that runs out, obtaining future supplies will be a major problem.

Making the cartridges is easy with a bit of practice and all that is needed by way of equipment is a shaped piece of wooden dowel of the correct diameter with a concave end with the recess shaped like a bullet’s nose that is used as a forming mandrel. Another piece of dowel, this time with a convex, bullet nose-shaped end is also required although a bullet can be used as an alternative.

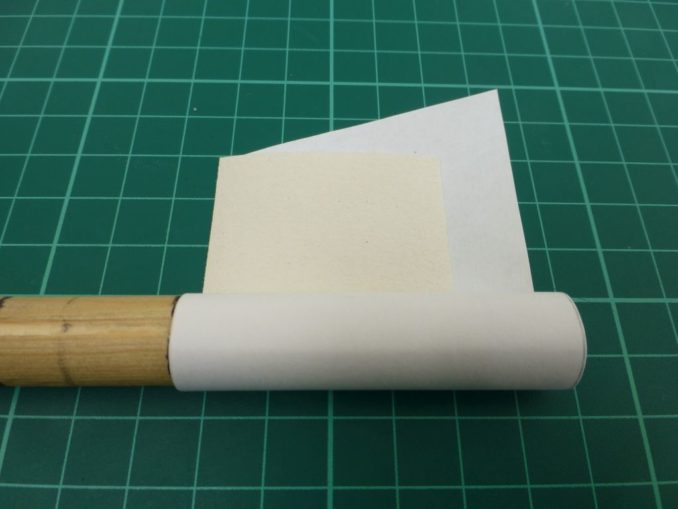

The first step is to place the ‘inner rectangle’ on top of the ‘little trapezium’ and to roll them tightly around the mandrel. The overlapping end of the tube is then folded into the hollow base of the mandrel and pressed firmly in place using the bullet shaped tip of the second piece of dowel. Leaving the forming mandrel in place, a Pritchett bullet is placed with its nose in the previously formed recess and the trapezium envelope is then wrapped tightly around both the tube and the bullet with the overlap this time being pressed firmly into the cavity in the base of the bullet. No glue or string was used in making these cartridges.

The mandrel can now be removed and the measured powder charge is poured into the cylinder using a small funnel. The end of the cartridge is then sealed by simply twisting its end into a tail and all that remains is to dip the bullet end in molten lubricant and the cartridge is ready to use. I usually make them up in batches of 25.

The lubricant, essential to keep the powder fouling in the barrel soft so as to make continued loading and firing possible, is made from a mixture of beeswax and animal tallow and it was the use of religiously offensive animal fats in cartridges that acted as a catalyst (some would say ‘excuse’) for the Indian Mutiny or Sepoy Rebellion of 1857-58.

The Enfield Cartridge in Use

The bullet mould that I have been using casts a bullet of .566” diameter which when wrapped in onionskin paper produces a .575” diameter cartridge which is a snug fit in the .577” barrel. Surprisingly, they are quite easy to load even after continued use of the rifle without cleaning, provided I haven’t mistakenly picked up two pieces of onionskin instead of one when forming the cartridge. This is easily done and has occasioned much merriment at the range.

To load the rifle it is held vertically with the muzzle uppermost. The twisted end of a cartridge is torn off between the teeth and the contents of the powder tube are poured into the barrel. The cartridge is then inverted, the lubricated, paper-wrapped end is pushed into the muzzle using thumb pressure and the end of the cartridge (powder tube and part of the outer wrapper) is snapped off and discarded leaving the bullet and its greased paper jacket in the muzzle. The bullet is then pushed down the barrel onto the powder charge in the breech with the loading rod giving it a couple of firm taps to ensure that it is fully seated on top of the powder with no air gap. The hammer is then pulled back to the half cock position and a musket cap is placed on the nipple. With the rifle shouldered, fully cocked and aimed it can then be discharged at the target with a squeeze of the trigger.

This cartridge loading procedure is both quicker and simpler than loading powder and ball separately and it has the added advantage of producing less fouling consequently leaving the rifle easier to clean after even a prolonged shooting session.

The American Civil War Cartridge 1861-65

At the outbreak of the war both armies were desperate for firearms and a bewildering array of muskets, rifles, carbines and pistols was purchased from anyone who was prepared to supply them. The infantry rifle most used by Union forces was the American made .58” Model 1861 Springfield and its clones while the Pattern 1853 .577” British Enfield and its derivatives were imported by the Confederates in huge numbers together with millions of rounds of both arsenal and privately manufactured paper Pritchett cartridges. As the war progressed, rifles and ammunition of all types picked up from the battlefields were used by both sides.

While an incredible variety of projectiles both dropped and fired continue to be found by metal detectorists operating on and around Civil War battle and skirmish sites, for the purposes of this comparison I shall concentrate on one type only, the ‘Burton ball’. The bullet I use is cast from a Lyman mould that replicates a dropped Burton ball recovered from a Civil War battlefield.

During the 1850s, James H Burton the Master Armourer at the Harper’s Ferry Arsenal, Virginia experimented with rifle ammunition concluding that the expander plugs used in the base of Minié type bullets were unnecessary and that his own design of hollow based bullet with three cannelures that carried a grease made of one part beeswax to three parts of tallow was superior in performance to that of the Pritchett bullet. As with the British cartridge, the American cartridge was further developed over the years but again it is upon the first type that I shall concentrate.

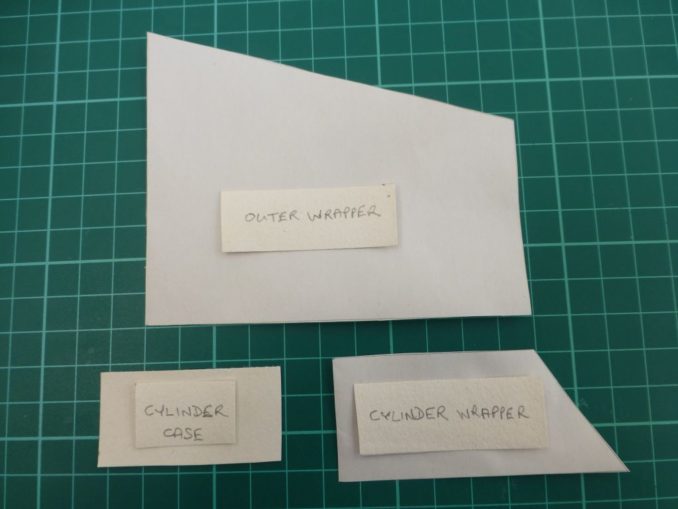

Like the Enfield cartridge, the American version is also made from three separate pieces of paper of different types one of which is referred to in contemporary manuals as ‘rocket paper’ but whereas the British version involves loading the part of the cartridge paper that is wrapped around the bullet into the barrel, the American cartridge is simply a container for the powder charge and the bullet is removed from the paper and loaded bare with the cartridge remnants being discarded. In the aftermath of battle, Civil War battlefields must have looked like Bournemouth beach following a summer Bank Holiday weekend.

Modern day American Civil War re-enactors make their cartridges using brown, paint-masking paper of two different weights together with a small piece of stiffer paper that gives the powder tube some rigidity.

As with the Enfield cartridge, the American one is formed using a wooden mandrel around which the paper is rolled. However, unlike the British version the base of the powder tube rather than being merely pressed into the hollowed base of the former, is carefully folded and glued over a flat or slightly dished surface. Then, instead of being incorporated into the cartridge dry and in an inverted position, the lubricated Burton ball is reversed and the pointed end is retained by choking and then tying off the end of the paper tube with a length of linen thread.

The Burton Ball Cartridge in Use

According to an 1856 US War Department report:

“To use this cartridge, tear the fold and pour out the powder; then seize the ball end firmly between the thumb and fore finger of the right hand, and strike the cylinder a smart blow across the muzzle of the piece. This breaks the cartridge and exposes the bottom of the ball; a slight pressure of the thumb and fore finger forces the ball into the bore clear of all cartridge paper. In striking the cartridge the cylinder should be held square across, or at right angles to the muzzle; otherwise, a blow given in an oblique direction would only bend the cartridge without rupturing it.

Cartridges constructed on these principles present a neat and convenient form for carrying the powder and ball attached to each other, and they obviate two important defects of the elongated ball cartridge commonly in use, viz: the reversed position of the ball in the cartridge, and the use of the paper wrapper as a patch. So far as they have been tried in the hands of the troops, they have been found to answer a good purpose.”

As I have only recently come across the above document, I have not yet had the opportunity to try snapping off the cartridge by striking it against the muzzle of the rifle but loading the powder and bullet is otherwise straightforward.

Findings and Conclusions

As making the British cartridges requires neither gluing nor tying, they are quicker and easier to produce to a consistently uniform high quality. The US cartridges are more complicated requiring additional steps in their manufacture and they are more easily torn and ruined at the tying-off stage unless great care is taken when choking the outer wrapping paper. The bullets also have to be pre-lubricated and handling them makes things a bit messier while the precise folding of the paper closure to seal in the powder seems unnecessarily complex and time consuming when a simple twist suffices in the Enfield cartridge.

On the other hand, the greased exterior of the British cartridge is prone to contamination with dirt and spilled powder and this can make loading difficult and could damage the barrel. The lubricant on the US bullet is protected by the throwaway paper wrapping but it can be fiddly to remove from the cartridge when there is a risk of it being fumbled and dropped. Perhaps this is one of the reasons why so many perfect, unfired bullets are still being found by metal detectorists?

I am somewhat puzzled by the reference in the above quote to the ‘two important defects’ of the British cartridge, namely the reversed position of the bullet and the use of a paper-patched round. The orientation of the bullet in the cartridge makes no appreciable difference as once the powder has been poured, the whole cartridge is simply inverted and its base containing the paper-wrapped bullet is inserted into the muzzle. This makes it much less likely that the bullet will be dropped during loading and, in my experience at least, makes loading the piece both quick and efficient.

Also in the 1850s, paper-patched bullets were beginning to be used in target rifles to reduce the amount of lead deposited in the bore that builds up causing a reduction in accuracy and is difficult to remove. Also, as bullet diameters were being reduced in order to increase velocities, leading became more of a problem and the next generation of British breech loading military rifle, the Martini-Henry, used paper-jacketed, hardened lead alloy bullets in self contained brass cartridges until the advent of the full metal jacket.

The main advantage of the US cartridge, so far as I can make out, is that as the paper outer wrapper is not loaded around the bullet, the type of paper used is not critical and old newsprint or pages torn from books could be used in an emergency. With the Pritchett ball the thickness and strength of the outer wrapper is absolutely crucial to success.

The proof of the pudding (see what I did there?) would lie in the ease of use and accuracy of the two types of cartridge under battlefield conditions, however for our purposes at least we will have to be content with their use at the rifle range. So far as ease of manufacture, use and convenience are concerned, I would have to say that the British Pritchett cartridge wins hands down. To date, and I still have lots more experimenting to do with powder types, charges and lubricant composition, I have found little difference in accuracy using 65 grains of 2F powder. Both types of ammunition perform perfectly well and both would be devastatingly effective against enemy troops. There is in truth little to choose between them.

When it comes to precision target shooting it is a different matter and here I think the US cartridge, which to all intents and purposes is the same as loading separate components, has a slight edge producing tighter groups and thus potentially higher scores. The fact that I know of no competitive shooters who use Pritchett balls and lots who use Burton balls bears this out but although I’m no historical re-enactor, using authentic, period-correct replicas of British ammunition in my 165 year old rifle nevertheless gives me immense personal satisfaction but I have to concede that if I were interested in competitive shooting, the Burton ball would be my favoured option albeit not in a paper cartridge format.

© text and pictures Tom Pudding 2022