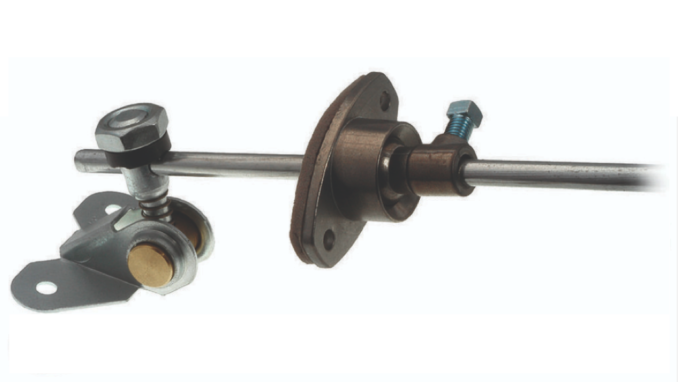

Splitter Damper Bracket Assembly, Hardcast – Licence CC BY-SA 2.0

I hated school, but I enjoyed technical drawing. One reason was that I got it from the very first day. For some reason, I could visualise in 3D those flat drawings. I guess my brain just worked that way. The teacher, Chippy Carpenter, and I got on. He was one of those old fashioned teachers who were interested in getting the kids to learn and with me it was easy, he gave the lesson and set a task to draw. I nearly always was able to whizz through the exercises and then help classmates, taking a load off of his shoulders. When it came to choosing ‘O’ Level courses of course I chose TD.

Unfortunately the next year we got a new teacher who was totally useless. One of the first lessons he gave was on view projection and he confused first angle projection (as generally used in the UK) with third angle projection (as used in the US). I had the temerity to tell him he was wrong and from then on he hated me. But TD is one of those subjects where what you draw is either right or wrong so he had to continue to give me good marks even if he continued to play a silly game of calling me by a different name every lesson.

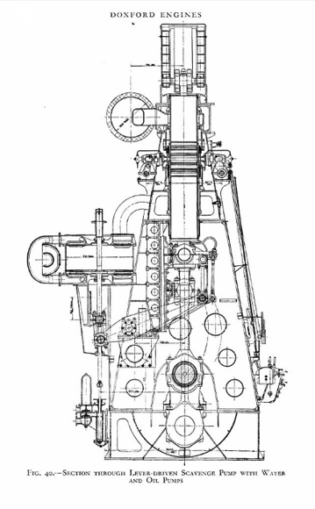

Lever driven scavenge pump, Terry Whalebone – Licence CC BY-SA 2.0

When it came to leaving school we all had an interview with the careers master, which just happened to be good old Chippy. He totally approved of my wanting to be a draughtsman and got me interviews for an apprenticeship with 3 local companies. In the meantime, a friend of my Dad got me an interview with the company he worked for, at that time called Babcock and Wilcox Ltd. Babcock designed, manufactured, erected and commissioned steam boilers for power stations, industry and ships all over the world and employed thousands.

I went along to all four interviews and got offered three jobs. I never wanted to work for Cambridge Instruments as it was mostly electrical work and wiring diagrams which didn’t interest me and my lack of enthusiasm was obvious to the interviewer. So my choice was Simms Motor Units who made car parts, Standard Telephone and Cable or Babcock.

It was the Babcock apprentice scheme that sold it to me. First-year in a training workshop using lathes, mills, shapers, welding and wiring. Second-year in the London office, eight months in the Drawing Office and four months in the Estimating Department. Third-year in a company factory in Oldbury, living in the companies Litchfield apprentice hostel, with one month in various departments and two months at the company welding school. Year four was to be on a UK construction site. Year five was back in the London office in one of the drawing offices. At every stage, we were to enrol in local colleges for day release in my case the path was to be a general engineering course (to make up for not taking ‘A’ levels) then ONC and HNC.

Back at school, I was summoned to see Chippy who wanted to know why I had turned down two job offers. What was I playing at? These were good companies! I explained I had accepted the Babcock offer and showed him the professional paperwork laying out the course and the wages. In the end, he asked me for the name and address of the Babcock training officer so that in future years he could suggest them to pupils.

On my first day at work (26th September 1966) we reported to the Euston offices for a weeks induction, lots of chats from ex apprentices, films about the company, a visit to the ROSPA exhibition which lived long in my memory and finally we were told that the training workshop had not been finished building yet. We were to work in various departments of the Dewrance Valves factory in Southwark (a Babcock Company), while it was being finished there. I was allocated to work with a lathe setter. His job was to set up the lathes so that the, mainly, lady operators could churn out thousands of identical small parts like valve spindles. The training workshop was right next to the area I was allocated to so at the first opportunity I went to have a look. There was nothing there! Just an empty space, work on it was still to start! I got chatting to a Dewrance apprentice who told me the discussions about the Training Workshop had been dragging on for months but work was to start next week.

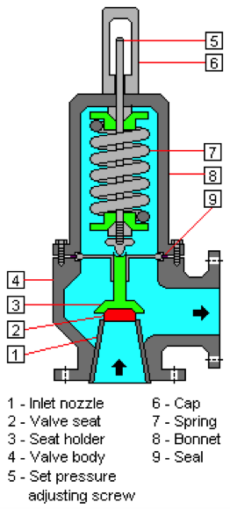

Schematic diagram of a conventional spring-loaded pressure relief valve, Mbeychok – Licence CC BY-SA 3.0

I learnt a lot while working with that lathe setter. Well, any young lad would, working with 30 or so randy lady and girl lathe operators. I lost count how many times I was groped or my bum was pinched and it was the old married ones who were the worst. I struck up a friendship with one of the younger girls, about the same age as me, and things died down, but woe betide any of my fellow apprentices who visited me from other areas.

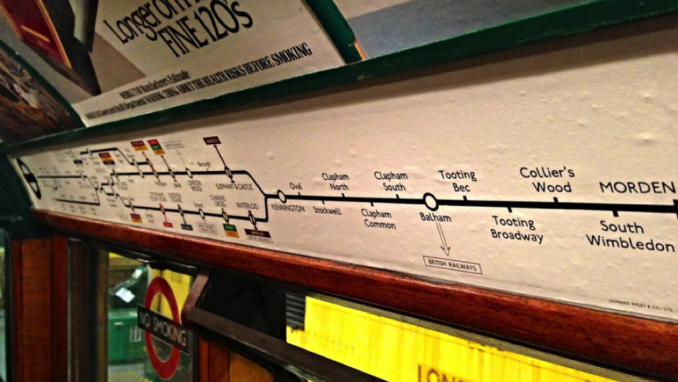

There were two six spindle automatic lathes at one end of the floor I was stationed on and I got to chat to the fitter/operator, Bill, finding we had a common interest in football. At the time I was living in Finchley and used the Northern Line to travel to Borough station daily. A few days later I got on the tube to find Bill sitting there. We got talking and he said he lived in Barnet. My Mum had been brought up in Barnet and had loads of relatives in and around the area. By the time we got to Borough we had established that he was married to my mother’s cousin! It’s a small world. After I had moved on from Dewrance we often met on a Saturday afternoon at Barnet FC’s Underhill ground. ‘Uncle’ Bill lived to a fine old age and I took my mum to his funeral where she met many relatives she only previously knew of.

The Northern Line, Andy Walton – Licence CC BY-SA 2.0

The Training Workshop eventually opened, but not before 2 of the 26 of my Apprentice intake had decided that it wasn’t for them and resigned. So 24 of us Babcock apprentices and 4 Dewrance apprentices moved in. We each had our own bench with a locker and vice and were set off making tools for ourselves. Over 50 years later I still have and use many including a hammer, engineer’s square, scribing block and several sizes of engineer’s clamps. It was a fantastic introduction to engineering.

In August we were moved back to the Euston offices. I was sent to work in the main drawing office where there were around 250 draughtsmen. I started on the Damper Section which meant nothing to me. I soon found that dampers were aerofoil shaped blades that controlled the flow of gas and air along flues and ducts. They turned on a spindle that protruded through the side of the duct and was turned by an actuator, levers and linkage. I was soon drawing damper operating gear for a power station in South Africa. It felt good to know that what you were designing was going to be built and installed in a real-life situation.

Splitter Damper Bracket Assembly, Hardcast – Licence CC BY-SA 2.0

Four months later and I was moved on to the Check Estimating Section. Another new experience for me. When we tendered for a project the designers came up with the sizes and principal of the equipment for the boiler island, supporting steel, boiler, flues, ducts, fans, air heaters, economiser, dust collector, coal handling plant (in those days they were nearly all coal-fired boilers), mills and burners, pipework, pumps and all the dust and ash handling plant. The Project Drawing Office put it all together and produced the design and layout drawings and the estimators put a cost to everything, whether made in house, made by a subsidiary or bought in. The Project Department put the bid together, drawings, costs with a profit margin added and technical information, all of which were submitted to the client and fingers were crossed and prayers said.

When we got an order, the contract side of the business took over and the design was detailed. At this point, a check estimate was produced. The idea was to ensure that the design could be produced for the allocated costs. We had just sold the first 3 boilers at Drax PS and my first job was a check estimate of the integral pipework, this is the pipework that joins together all the internal parts of the boiler. I had a heap of detail drawing showing bends, end preparations, welds, lengths and raw materials. I had schedule showing shipping costs, I had man rates for erection, welding and testing. My job was to put all this accurate information together and to see how near the guy who had used his experience and expertise to cost it in the tender stage had been.

More pipes for power, Les Chatfield – Licence CC BY-SA 2.0

After 3 months of colouring each pipe on the drawings as I costed them, I got to just over £1.4 million. Don’t forget these were pre-computer days and despite having a basic pocket calculator most calculations were done by hand using pencil and paper. My supervisor chuckled when I showed him my final costing. Unknown to me he had been doing the same exercise and had come up with the same cost within £100. He then showed me the original costing and it had been £1.41 million. He bought me a cream cake when the tea trolley came round that afternoon.

It was then back to the Damper Section to finish off my year in the London office. If I thought I had got away from Drax I was wrong. I was now set to work on various bits of damper operating gear for the number 1 boiler main flue to the chimney. The original Drax had one chimney with three internal cores one for each boiler. The flues were interconnected so that boiler combustion gases could be directed to a different core for maintenance. In case you wonder, flues carry waste hot gases, ducts carry combustion air.

I had to take my annual leave over the summer before going to Litchfield in September for my third year. A friend and I had been saving hard all year for our first foreign holiday without our parents. We had booked two weeks in August in Majorca, at a little place called Cala Murada. Needless to say, we had a fantastic time, I met a cracking German girl who I corresponded with for a while when I got back to England. Of course, it faded out by the Autumn like most holiday romances do.

Cala Murada – panoramio, Anka D. – Licence CC BY-SA 3.0

I will complete my apprenticeship adventures in the next thrilling instalment.

© WorthingGooner 2020

The Goodnight Vienna Audio file

Audio Player