Unless one is rich enough to have a yacht custom-built to one’s own specification, which I certainly was not, one has to choose a “Production” model in much the same way most people buy motor cars.

A few Boat Builders make the basic hulls and decks to standard designs in their own factories and some of the auxiliary equipment too, like the carpentry and woodwork in the cabins. Others go to the opposite extreme and buy-in practically everything from specialist suppliers. Their operations are essentially ones of assembly rather than manufacture.

Most companies have a policy of attracting customers with the lowest price they can manage for a very basically equipped yacht, sometimes with “Optional Extras” being available at a pre-determined price. A few will also be prepared to “customise” their standard offering but those at the “Assembly Plant” end of the spectrum are unlikely to be willing to do so because their business depends on making a profit from lower margins on higher volumes and anything “non-standard” is anathema to them.

As a “Newbie” to the world of yachts perhaps I had more queries than most but I found I was strongly influenced by the different reactions of individual boat builders. Some were constructive and responsive, others seemed to regard some of my queries as unnecessary and tiresome.

At the time I didn’t know as much about the subjects discussed in this article as I do now but I did ask potential builders about a lot of them.

Instruments

Most Production yachts in the 1990’s had minimalist instrumentation, usually consisting of a Helmsman’s Compass, a depth sounder, a log to measure speed through the water and a combined anemometer and wind-direction sensor. Civilian use of GPS and electronic charts and displays were in their infancy and widespread use of sextants had only recently become less common.

In addition to the normal instruments I therefore added a Radar, one of the very basic monochrome chart plotters available at the time showing coastlines, buoys and a few depths but not a lot more, and various additional meters above and below decks displaying navigational data from electronic signals generated by mechanical sensors or antennae of one type or another.

As I gained experience I dispensed with some of these “goodies” as they stopped working for one reason or another – wires and electronics don’t mix very well with hot, humid, salt-laden tropical air.

Items that repeatedly went wrong were the wind measurement instruments and the speed through the water log. In both cases the failures were due to damage to the rotating parts of the sensors or to corrosion in the very fine wires carrying electronic signals from them to the electronics in the boxes displaying the data in a form humans can interpret. After several years of sailing I found I could judge the sail plan needed at any time by the feel of the wind on my face, the forms and height of the waves, and the yachts response to these conditions.

The instruments I found most useful were those displaying positional data with course and distances for the planned and actual voyage, and the depth sounder.

After the original GPS antenna failed during my first full year of ownership I always carried a hand-held GPS and plenty of in-date spare AA batteries as a back-up – and a lead-line in case the depth sounder failed.

Modern yachts are more likely to have sophisticated chart plotters displaying all these data and more on attractive multi-colour screens. These are very useful when working well but if failures occur the skipper is likely to lose everything at once and repairs are expensive or not available at all in remote locations.

The same applies to many electronic engine management systems with push-button starts created for industrial societies to meet fuel economy and pollution objectives set by their Governments. Its hard to start such engines by hot-wiring them when things go wrong.

There’s still a lot to be said for the old dictum to KISS (Keep It Simple Stupid).

My radar wasn’t needed very often but by jove it was important in fog, when approaching an unknown coast, and for collision avoidance when there were other vessels nearby, especially at night. Large ships moving at 15 knots or more, fishing vessels changing direction frequently without warning and ferries crossing ones path as they plied to and fro are a few examples of times when I thought my Radar was the most important instrument on board.

Communications

I regarded a VHF radio with its antenna at the top of the mast as an important and frequently required tool and also ordered a short-wave radio for long-distance communication. The latter needed an insulated backstay to act as an antenna but before the transceiver itself was installed I learned it hadn’t been type-approved by the European Union even though it was perfectly acceptable for use in most countries around the world.

It was too late to cancel the special backstay but the transceiver hadn’t been installed and instead I asked the boat builder to fit an Inmarsat C set connected to its own relatively small antenna mounted on the pushpit rail. This provided text-only capability for short messages and weather forecasts via four Geo-Stationary satellites providing global coverage within 70 degrees north and south of the Equator.

Since then, software and amateur radio networks have been developed enabling long-distance cruisers to use their short wave radios to send and receive emails so they have the advantage of both voice and text communications – though many of them spend hours every day tuning-in to get the best signal.

I didn’t really regret the change I thought it prudent to make for legal reasons because the time that needs to be spent below decks tuning-in seemed to be a high price to pay for the additional capability. Later on I did buy an Iridium Network satellite ‘phone but that was only useful for a couple of years because the service-charge structure was changed and it became prohibitively expensive for the little use I made of it.

Deck Equipment

Anchors and chains are amongst the most important pieces of equipment on board and whole articles longer even than this one have been written about them. A windlass to haul them back from the seabed is virtually essential and I decided to have a high quality electrically powered one from the start.

I also thought a life-raft would be a good idea and had one strapped into a wooden cradle on deck between the mast and the spray-hood protecting the cockpit – like most insurance it cost quite a lot both new and in servicing charges and I never used it.

A small dinghy, preferably powered by an outboard motor is essential both as a means of getting ashore and as an ultimate safety option in the event of a problem. I carried mine on deck between mast and staysail with the outboard motor on a bracket at the stern or in a cockpit locker for long voyages.

Mooring ropes need to be as many as can be carried with at least two extra-long ones and the equivalent applies to fenders – short, skinny ones are OK when moored to a floating pontoon in a quiet marina but there’s a need for at least two much larger ones fore-and-aft if up against an overhanging wall or in wind-driven waves. I always remember another sailor describing a stay during strong winds at Peniche marina in Portugal as being a “fender-popping” experience.

Although separate from the boat purchase I carried for a long time a wooden ladder on a side-deck as a result of my experience on the charter boat in the Canary Islands. It was particularly useful in harbours with a large tidal range where it was necessary to moor to a wall. I could use it as a means of getting on and off the yacht even when the tide was out, as well as protection for the fenders. By the time it eventually fell to bits through corrosion of the tie-rods holding the stringers together I was in countries where anchoring was the norm and a fender board was rarely needed.

A “Handy Billy” comprising two blocks threaded several times with a rope passing over pulley wheels in each of them is invaluable because the mechanical advantage it provides is useful for all sorts of tasks. I used mine for lifting things on and off the yacht during maintenance and the dinghy when at anchor, and even on one occasion in South Africa to hold a marina pontoon together in a gale when one of its shackles broke threatening major damage to all and sundry.

Accommodation, Living Conditions and Electrical Systems

Most “Production” yachts in the size range I was interested in were fitted below decks with two cabins, a general use table and one on which to lay out paper charts, various lockers, fuel and water tanks, a basic galley powered with bottled gas, a “Heads” (marine toilet) discharging direct into the sea, 12 volt batteries powering cabin and navigation lights and other electrical systems, and an engine complete with shaft and propeller.

I decided extras were needed to improve life-support and comfort on board and that I would also have an inverter to transform 12 volt DC battery power into 240 Volt AC with associated circuits and control switches supplying a microwave oven, a car-type entertainment radio with Tape/ CD player and loudspeakers, and power points for charging 240 V AC appliances. I also asked for extra storage lockers, a holding tank for toilet waste until far out to sea, and other desirable features like a refrigerator, a cabin heater, a desalinator to make fresh water from sea water and so on.

All these increased electrical load. That is not a particular problem when staying regularly in a marina provided the yacht has a battery charger that can be supplied with shore-power but is not so easy if undertaking long voyages or staying at anchor for long periods.

Under those circumstances management of electrical power demand and supply is critical. My yacht had three 100 amp-hour AGM batteries giving a practical capacity of about 150 amphours whilst still having enough charge left to start the engine – Advanced Glass Mat (AGM) batteries have a solid electrolyte and continue working after heavy abuse. I found out later my space-limited battery capacity was the bare minimum needed and the refrigerator alone consumed close to one-half of usable charge every 24 hours when in the tropics. Occasionally I had to switch it off to conserve power and diesel fuel.

I had appreciated early on that recharging the batteries with an engine-driven alternator needed to be augmented with other means – and I had no room to carry a stand-alone petrol-driven portable-generator and its fuel. I thought a wind generator could be the answer and bought one to be fitted to the yacht whilst it was being built. It worked quite well but was incredibly noisy and I tried other forms of “Green Energy” later on – but I’ll leave a discussion of those until later articles.

Electrical systems need to have a good Earth for safety reasons. I mentioned that in the previous article when my yacht’s copper strips around the hull were visible on a photo of the chain plates taken during factory construction. That copper network was connected to a compact “ground plate” on the outside of the hull built from highly conductive material with a honeycomb construction (don’t coat it with anti-fouling paint or it won’t work).

The desalinator is worth a mention because it worked on the principle of Reversing the Osmosis described in an earlier article by applying high pressure to one side of a semi-permeable membrane that allows molecular water to pass through for collection but stops particulates and larger molecules like salts. It also stops bacteria which are a good bit smaller than salt but still about 2,000 times the size of a water molecule. In passing I note the coronavirus is smaller than the smallest bacteria but still about 500 times larger than a water molecule so I guess reverse osmosis would also strip out the coronavirus even if face masks do not (a fierce debate continues on that last point and seems to centre around the argument that viruses don’t travel about on their own but are usually piggy-backing on water droplets or aerosols that some face-masks can stop).

Two types of pressurisation methods for desalinators were available – engine driven or electrically powered from the boat’s batteries. The same idea is used in most large-scale desalination plants.

Mine was electrically driven and not very helpful – it used a lot of power and whilst it worked OK when new or recently serviced it often failed after storage periods when it wasn’t needed. In the end I took it out and threw it away.

My yacht had two fresh water tanks, together holding close to 260 litres and when I was at sea for long periods in later years I was usually single handed so that volume and occasional rainfall kept me going without needing to rely on a strategic reserve of another 25 litres or so carried in a collection of coke bottles stuffed into the corners of stowage areas not useful for anything else.

Hull Penetrations, Propellers and their Shafts

Several items require a penetration through the hull. All such holes are equipped with manually operated valves with some normally remaining closed. Others are often left open for convenience including those for intake of engine cooling water, discharge of waste water from the Galley and Head sinks and any drains carrying away sea-water from the deck and cockpit.

It is prudent to operate all valve closures occasionally because some are hard to access and can become stiff when not used for a long time. I discovered that in Darwin after several years of cruising where it was a condition of entry into a marina to have all penetrations soaked in hospital-grade anti-bacterial liquid for 24 hours to limit barnacle growth on the Marina’s lock-gates (there’s a huge tidal range in Darwin and high water temperatures inside the marina that the barnacles love). Also to carry tapered wooden plugs nearby that can be hammered into the opening if a valve fails.

Three inescapable penetrations in a boat with an internal engine are respectively needed for cooling water intake and discharge and for passage through the hull of a rotating shaft conveying the engine’s power to a propeller. Propellers come in various shapes, sizes, designs and efficiencies – books have been written about them alone.

A normal owner will mainly be interested in the number of blades his propeller has and whether their angle to the shaft can be varied. That is important because it is often difficult to drive a yacht backwards with a fixed blade propeller and one with variable blades makes reversing much easier. It is useful too if the propeller blades can fold or change angle when the yacht is moving under sail so they don’t act as a brake by presenting resistance to water flow over them.

A complication arises because stray low amplitude electrical currents can be set up between propellers and other underwater metal parts and the “ground plate” mentioned earlier. These can cause loss of material from the metal feature in a process known as Galvanic corrosion because an unwanted but unavoidable electrical cell can be formed between the feature and the Ground Plate.

Protection against that possibility can be provided by installing a sacrificial anode nearby made from a material more prone to this type of corrosion than the feature such as the propeller or metal “shoe” in which the rudder shaft is fitted. This is important because sacrificial anodes are much easier and cheaper to renew during maintenance than propeller blades and rudder shafts. Yachts with exposed propeller shafts typically have an anode clamped around them near the propellers. Others, such as the type I eventually bought have conical ones screwed into the end of the shaft immediately behind the propeller.

Another thing worth noting about propellers is that flotsam in the water, including ropes dropped overboard, can be drawn between the blades by the flow of water they create and wrap around them so tightly knots can form and prevent the propeller from turning thus causing an abrupt engine stoppage and loss of control over the boat’s movement.

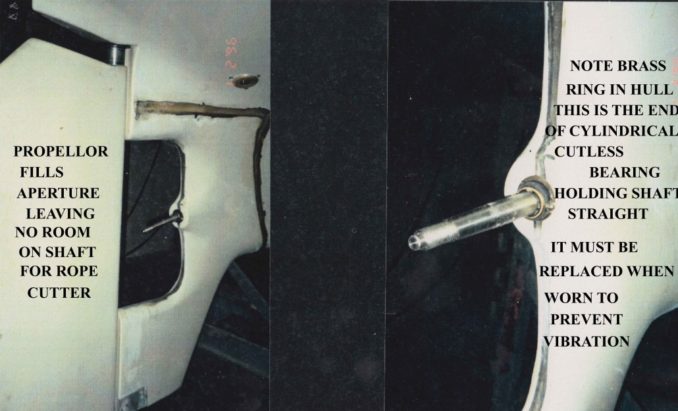

Yachts with externally exposed propeller shafts can have a “rope-cutter” with sharp edges fitted to the shaft to minimise that possibility by chopping up the flotsam or rope into small pieces that can pass by the propeller without difficulty. Others, such as the one I finally settled on, attach more importance to minimising the risk of mechanical damage to the propeller shaft and rudder and don’t have room for a rope cutter. All have a bearing where the shaft emerges from the hull to keep it straight when rotating.

© Ancient Mariner, Going Postal 2021

Is an engine really necessary?

Some purists cut down on all these complications and costs by deciding to forego comforts like a refrigerator, an electric windlass and a Radar and choose a boat without an engine – but they often end up having to be towed in and out of harbour, and sometimes damage others by their consequent loss of control when sailing conditions are difficult (reminder for a later article).

But it can be done. I once met a young American single-handed sailor in Hampton, Virginia with whom I subsequently kept in touch as he sailed a year and more ahead of me down to the Caribbean and across the Pacific to New Zealand. He did have an engine when I met him but instead of using it he frequently chose to scull his yacht using a long oar mounted on a fulcrum at the stern.

Whilst staying at Whangarei in New Zealand’s North Island, he had the engine removed and the shaft penetration and propeller aperture sealed. He completed a circumnavigation via South Africa that way but it must have been hard work – especially when sculling into the wind!

To Be Continued…

© Ancient Mariner 2021

The Goodnight Vienna Audio file