In my last piece I talked through the attempt to refurb a lawnmower, replacing the rusted body, which is now back to happily chewing all it crosses, without spitting bits out at random. As long as you ignore the loud rattle from the front wheels, it is back to work as new.

The piece was a distraction from the heavy politics raging at the time and did spark some conversation about the benefit to your mood of pottering about or having something practical to achieve. For many of Puffin readership age, an ideal is having a shed to escape to – their own domain, free of external nagging, news, television and other day to day hassles.

My shed is basically a store of unwanted tat – the rarely used BBQ, old tyres, a dustbin of forgotten wood offcuts, various hanging baskets last used years ago. It is full to the point of struggling to close the door, so not the utopian ideal to hanker for.

One particularly boring day at the office – and believe me there are many – I decided to do something about it, it was time to find a new project. My work is probably something Bob Crow would dream of – office based, sitting around working with a mostly young, female workforce. In reality it involves hours of pointless meetings, work creation and processes designed to keep many busy for sometimes flimsy reasons thought up years ago. The gender mix means much of the time is smoothing ruffled feathers and finding a way out of the latest spat. I’d rather be driving a digger, but that’s the career I have and it pays the bills.

So time for a project – this time on a larger scale. There’s nothing that needs doing around the house, the garden is ok, but I’m the only one that ventures into it, so not a great deal of reward toiling in there, particularly with the Northumberland spring weather usually involving cold easterly winds.

What do to? I wanted to find a physical activity that would be rewarding – not financially, but having the feeling that you’d achieved something, no matter how small, with the results you can see at the end of a day. If it meant working with like minded people, perhaps on a common interest then all the better – banter and friendship is always good. Flexibility is important – I can’t dedicate a lot of time to it, somewhere that a few hours helping out now and then would be ideal.

Some in this position volunteer to work at Beamish – the large outdoor, award winning museum of trams and all aspects of Georgian and Victorian life, but that is a very professional business and would require a decent number of hours. Similarly Kynren, a huge summer enterprise built upon volunteers demands full weekends and evenings to participate (then wonders why it struggles to find people). For both of those you really need to be retired or semi-retired. I’m ten years off that position at the moment so not an option.

One place I remember from when the kids were young with fondness is Tanfield Railway in County Durham. It is a small heritage railway, run by volunteers less than 20 miles from home. It boasts the world’s oldest continuously operational Engine shed, a few miles of track and a selection of smaller engines, trucks and carriages. When we used to visit, the kids were going through the ‘Thomas’ phase and the lasting impression was the friendliness and particularly the relaxed atmosphere – you could wander around the sheds and sidings unhindered, at your own risk.

I mentioned the subject of considering ‘doing something’ to Mrs SD, who scoffed at the idea claiming I’d be spending time with oldies – somewhat rich from someone who lives at the tennis club – so she has no grounds to object! I plan to be active on Saturday afternoons, when she is, of course, playing tennis, so no family duties are being ignored.

Their website includes a ‘volunteer’ page, so I filled that in, and received a call less than an hour later. A well spoken old gent asked for a few details and offered a tour of the facilities to suss me out.

I met with John a week later, he seems to be one of the main driving forces of the enterprise, looking after new recruits. A retired surgeon, he has been involved with the railway since it started in the 1980s when they took on what was then a single shed, storing engines for Beamish, and an overgrown track bed, no track. The main shed is at an intersection between two old coal lines and they had to build everything – stations, track, even dig out and replace a bridge that had been ‘dropped’ onto the trackbed, by the Coal board so they no longer had responsibility to maintain it. It has taken them many years of work to get to where they are today, with two stations, some miles of track and a well functioning and supported engineering department restoring and maintaining carriages, tank engines and trucks. They publish a daily blog showing what pottering has been done.

The engineering setup is very impressive with the serious machinery needed to maintain such large pieces of kit. As well as the operational equipment, they also have lathes and milling machines from an old shipyard, all run from a beam and small steam engine that was used up to the late 70s. The introduction of electricity to the site around 2000 meant they were able to move on to newer electrically driven lathes and machinery – i.e. less than 50 years old. I met a number of volunteers, all dedicated to their areas and enjoying what they do, all very welcoming.

I have been assigned to engineering as an unskilled labourer, welcome to come along whenever I can. At present Saturday afternoon is the only option for me. Saturdays are not a steaming day and the main activity is in the carriage and wagon restoration, though this can change when they have gala days and in school summer holidays. Sadly most outdoor work is done during the week – the blog gives you the rhythm of work, made up of days in the sheds pottering and making parts, days on the permanent way and others restoring stock. They have an extensive collection of old trucks and carriages, many in a really poor state ready to be rescued and restored to full working order.

In the run up to my first day I had to get myself kitted out – some steel toecap shoes/boots, scruffy clothes or overalls and a hard hat as the main shed is having the roof replaced and is a hard hat area. Luckily I’d come across a new shoe shop in Cramlington selling steel toe capped boots for £25 a pair – they look like trainers, comfortable and include steel in the toe and sole. A trip to Arco and I found a boiler suit (overalls) and hard hat for a lot less than expected, so all set.

Naturally you don’t want to turn up as the newbie with clean overalls so a few minutes kicking them around the garage floor improved the appearance a little and made them look a little less brand new.

First day was spent painting a goods wagon – recently rebuilt, it needs three coats of ‘container paint’ – heavy oil based stuff that’s not put off by the rain, so I spent the afternoon on a ladder in the drizzle finishing it off. Not the most amazing job to start with but you can see where you’ve been and the company of two others meant a decent afternoon of chat as we got through it.

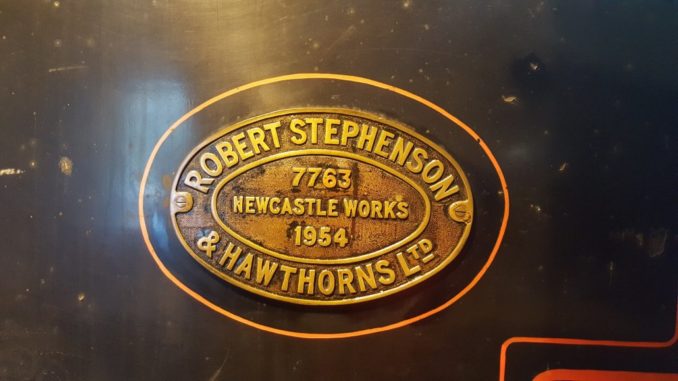

Last weekend was more fun, with rain falling again, I was a little worried I’d be on painting in the rain duty again, but that was not the case. The bloke in charge asked me to ‘help out Stuart oil his engine.’ Stuart was a shy unassuming man just finishing his lunch who was a bit taken aback to be offered help, but accepted it. We headed into the storage shed to work on a huge saddle tank engine, no. 38 – 50 tonnes of kit built in 1958 as one of the last steam engines made.

Stuart was very proud of the engine, having being part of a group that rescued it from its final resting place at Shilbottle mine. It had been restored and in use for a number of years on the railway. Over the years he’d bought out the other partners who had either moved on or passed away and now was sole owner. He talked through the history of the loco. It had been one of a batch commissioned by the National Coal Board to shunt coal trucks at local mines. This was one of a small number that went to Ashington Colliery and were in use, 24 hours a day up into the 70s, equipped with a 6v electrical system for running and footplate lights. I remember seeing the engines when very young as we went to shop at the neighbouring supermarket in Ashington (Prestos) and they were the inspiration for the model railway previously described – so one of those very engines – something that struck me later as if not Karma, then a remarkable coincidence.

An extremely powerful engine, with the same power as a black 5, it had not been moved in four or five years as it is on the list to be restored.

Having been in use on the railway, the boiler inspection expired and it needs some work. Boiler work is always prohibitively expensive, so it is inching towards being mended – Stuart being sole owner was saving up. All the dials and brass elements of the footplate are out, the 1000 gallon water tank loosened off, waiting boiler removal. The oiling was needed as it was to be shunted later in the week as part of a reshuffle of the kit as work was being carried out on the ‘running shed’ roof – the shed used by those locos in operation which needs new beams. It has to be emptied and the contents distributed amongst the other three or four usable sheds while the work progresses.

We added oil to each moving part in some cases by simply turning a wheel that drove a pump to oil more inaccessible locations, or topping up small reservoirs by removing corks in key parts. Most were on the outside of the engine, but some were below the boiler. Luckily Stuart was a lot smaller than me and was able to squeeze between the frames and get to the more difficult locations. Just as moving anything that’s not turned in years, he expected them to be challenged by getting it to move, expecting it to need two shunting diesels paired up to get it on the move.

After an hour or so of prepping, the boss came along and mentioned a carriage had its annual inspection ‘tomorrow’, so could we oil that. Stuart then mentioned he also owned the carriage in question, along with two more engines! Most of the carriages in use at the railway are 1880s, 6 wheel early boneshaker carriages – wooden seats with no corridor. Stuart’s coach was a 1904 GWR bogie carriage – so much larger and a technological leap forward. It was designed to run at up to 90mph in much greater comfort. Each wheel and moving part needed oil – so a run around, checking reservoirs on the 8 wheels, then all the brake parts, all done in an hour or so.

All in all an enjoyable session, the overalls are now suitably dirty and crumpled and I’ll be back in a fortnight when next free. The restoration is never ending – most of the engines are privately owned and to be honest some of the owners have bitten off more than they can chew, pottering around in extreme old age with huge tasks to tackle. I’m probably missing the point looking at it in that way, as they’re happy tinkering, working with friends in mega-sheds, giving a reason to get up in the morning. Plus of course an aim – to maintain them and keep them from degrading further for another generation to pick up.

Footnote – the blog of the 21st shows no.38 successfully out of the ‘5 road shed’ as the reshuffle progresses.

© Text & images Sweaty Dave 2019

The Goodnight Vienna Audio file