As Energy Secretary Ed Milliband’s Net Zero cultural revolution gathers pace, this week he announced a nuclear renaissance. A new £14bn reactor is planned for Sizewell. Small modular reactors (SMRs) are being championed through a £2.5 bn initiative with Rolls-Royce for three such facilities in the 2030s.

Well recieved in mainstream media comment, the idea is of a quick-build factory-fabricated atomic power station delivered on a lorry to be assembled in a medium-sized shed. But is this wise, or even possible?

Small modular reactors are compact nuclear power plants designed to generate electricity on a smaller scale than traditional reactors. A single SMR may produce between 50-75 MW of electrical power but modules can be added incrementally and used in multiple on-site up to the top end of the small reactor definition of 300 MW.

In comparison to traditional nuclear power stations; the under-construction Hinkley Point C has two 1.6GW (1,600 MW) reactors. In other words, the equivalent of 30+ SMRs. Conventional thermal power stations were bigger still, with Drax (when coal-fired) tipping the scales at 4GW.

Protagonists claim the modular nature of SMRs makes them suitable for remote locations, industrial sites, or regions with limited infrastructure. Because of their relative smallness, SMRs can be built at a central location and assembled elsewhere using modular techniques, allowing for quicker and more cost-effective deployment. Quality control improves.

Time is saved and costs are reduced as building in a controlled factory environment limits delays common in large-scale, on-site nuclear construction. Small dimensions also allow for simplified safety systems (often passive), and the promise of lower up-front capital investment, making nuclear electricity more accessible.

Critics note, however, that while these claims are in theory compelling, few SMRs are deployed at present, so practical evidence is limited. Nonetheless, supporters argue that SMRs could be a flexible, safer, and cleaner component of future low-carbon energy solutions. But is this true?

In terms of remote locations or supplying to power-hungry industrial complexes, this is not the strategy in Milliband’s Renaissance. The new generation of UK SMRs will be providing to the grid. Claims that they are small and modular also need to be examined.

Such things do already exist, but as repurposed submarine or ice breaker engines. In Russia, two KLT derivatives provide electricity and heat to the isolated town of Pevek in the far northeast of the country. The KLT-40 family originates from Taymyr-class icebreakers and delivers 171 MW of thermal power to produce 54 MW of electrical power.

© Google Maps 2025, Google licence

Aboard the Akademik Lomonosov, the world’s first operational floating nuclear power plant, two KLT-40Ss sit in the bay next to Pevek. The actual reactor vessels aren’t small at 7m x 7m x 11m. Not quite deliverable on a lorry, Akademik Lomonosov was built at the Sevmash shipyard on the Baltic. Upon completion, the 21,000-ton barge was towed around the Arctic to its new mooring. However, with the two reactors producing 100 MW this is still only 1/40th of the output of one of the old thermal stations.

There is also a history, albeit abortive, of SMRs in the USA.

From the start of the nuclear age, there was the thought that small nuclear reactors might have economic and other advantages over the standard-size plants we’re familiar with today. Perhaps by reducing the substantial financial risk of a full-scale nuclear project, SMRs might be the best option for some applications?

In the 1940s, different branches of the US military researched and developed various types of small reactors. Between 1946 and 1961, the US Air Force spent more than $1 billion on an abortive attempt to develop a reactor to power long-range bombers.

The US Army Nuclear Power Program led to the construction of eight small reactors. Several of these were located in the same sort of isolated spots: Antarctica, Greenland, and remote Army bases.

But these proved to be costly, unreliable and complex to operate and maintain. Easily replaceable by conventional diesel generators, the Army cancelled the programme in 1976. The conclusion being that the development of complicated, compact nuclear plants of advanced design was expensive and time-consuming and that the costs of developing and producing such plants were so high that they couldn’t be justified.

British nuclear submarine,

Defence Imagery/a> – Licence CC BY-SA 2.0

The US Navy had better success with atomic power for aircraft carriers and submarines. But these have different requirements from today’s SMR proposals. A submarine’s nuclear reactor is designed to generate heat for propulsion and electricity, enabling long underwater endurance and operational autonomy.

The overwhelming advantage being that they enable a sub’s strategic imperative of remaining at sea undetected for long periods without refuelling. Added to which, naval reactors don’t have to compete comercially with civilian plants or other sources of power production.

With the submarine reactor being at the low end of SMR power output, perhaps one hundred would be needed to replace a thermal station. The lesson from defence is that the small nuclear reactor can have a unique capability but only if it alone fills a clearly defined objective.

Starting in the 1950s, a number of civilian small reactors were proposed in the United States. Seventeen with outputs of less than 300 MW were commissioned. None of them are in operation today. Many of these projects were prototype reactors that would contribute to the development of larger units.

Of these, Fermi 1 is the most famous because it suffered a meltdown in 1966 which inspired John G. Fuller’s 1975 book ‘We Almost Lost Detroit’. A 150MW unit, it operated between 1966 and 1975. Others were more successful but too costly. The 185-MW Yankee, also called Yankee Rowe, operated for 31 years, but its decommissioning took 16 years and cost $608 million.

The cost problem with small reactors is that the expenses associated with constructing and operating do not change in linear proportion to the power generated. A larger reactor requires less than twice the quantity of concrete and steel to construct as one half the size, and it can be operated with fewer than twice as many people.

The historical record is clear: Without exception, small reactors cost too much for the little electricity they produce, the result of both their low output and their poor performance. In the end, as General Electric concluded in a 1966 report, “Nuclear power is a big-plant business: it is most competitive in the large plant sizes.”

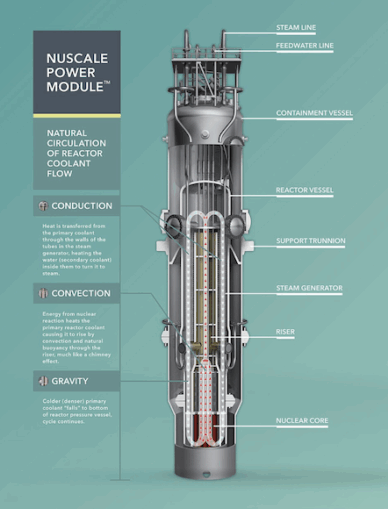

Returning to the present day and remaining in America, the NuScale Power Module is the first and only of a new generation of SMRs to receive design approval from the U.S. Nuclear Regulatory Commission. The manufacturers claim that four such 77 MW modules could power a desalination plant for a city the size of Cape Town and six could power an oil refinery. Twelve might generate close to 1GW of electricity and might replace a small coal-fired power station.

A diagram depicting a NuScale reactor,

NuScale – Licence CC BY-SA 3.0

At 76’ long and 15’ wide, the power-generating unit is not small. Added to which it only consists of the reactor and steam generator, the rest of the power station requires additional construction and transportation.

At 700 tons the reactor/generator is both heavier than the space shuttle and bigger than the biggest load ever carried on a British road. That record, at 640 tons, belongs to a transformer moved from Didcot Power Station in Oxfordshire to Avonmouth Docks in 2013. Requiring two lanes of the motorway and proceeding at a glacial 4 mph, the journey resulted in a 13-mile tailback along the M4.

Splittable into three modules, NuScale assemblies remain well north of the abnormal load limit and will require notifications, permits, escort vehicles, route surveys, risk assessments et al. And remember, that’s just the reactor and steam generator.

As for NuScale’s operational history, there isn’t one. In 2015, Utah Associated Municipal Power Systems and NuScale Power began a collaboration to construct 12 reactor sections with the aim of starting operations in 2023 at a cost of $3 billion. By 2018 costs reached $4.2 billion, with the collaboration cancelled five years later for a by then scaled-down version priced at $9.2 billion.

Analyst M V Ramana of Utility Dive concluded, “The engineers and accountants on the project were evidently unrealistic about the likely costs. Or perhaps NuScale preferred to gently break the bad news about how immense the bill would be. Or both.”

As of June 2025, NuScale technology has yet to enter the marketplace despite US Department of Energy funding beginning a quarter of a century ago.

A lesson here for the British taxpayer as they front-load the finance to Rolls-Royce for a design which doesn’t exist yet and which is neither small nor particularly modular. Added to which, Rolls don’t have to deliver until midnight on the 31st December 2039.

The suspicion being that the SMR project’s clearly defined objective is to provide Milliband with a Net Zero fob-off sound byte, and its accompanying unique capability is to tip money onto the shareholders at Rolls-Royce.

© Always Worth Saying 2025