Musings on the development of the Miles M20 prototype

Firstly, a reminder of where we started back in part one, I suggested in the first article in this series that the Spitfire was not an aircraft that was suited to development as the complicated wing construction was a very limiting factor. We have then meandered through part two which was setting the scene for part three, The Emergency Fighter, the aircraft which should have been developed.

It’s September 1940, The Battle of Britain is being fought over Southern Britain, the much lauded Spitfire is finally being produced in numbers in factories that have been set up at huge expense. It has been developed for five years and is complicated and expensive to build. It carries little fuel (and what it does carry is in front of the pilot’s face), it often needs to break off a fight to land to rearm in a time consuming operation. Many of them will be destroyed on account of it’s propensity to ‘ground loop’, that is to charge off to the side in a circle and tip over or collapse the undercarriage, on take off or landing. Along comes a fighter, designed and flown in 65 days, which meets just about every requirement for a fighter and could be knocked up in a well equipped shed.

What to do?

Develop the idea to produce an even better fighter, given the enormous development potential, or say “That’s all very well, but it might tip over on its nose if you land on rough ground or in water because of the fixed undercarriage and it’s not quite as fast anyway.” The authorities would have to admit to backing a wrong horse, to climb down and admit to having a procurement policy that could have led to the defeat of the nation or they would have to say “We’ve got plenty of Spitfires now thanks” so there will be no more development work on the M-20.

The prototype slid off the icy airfield on landing, ended up nosed into a gravel pit, was damaged and put aside.

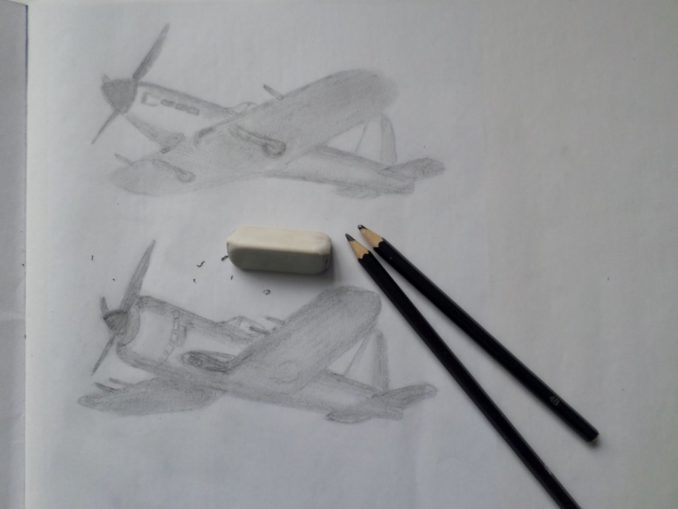

In this article I will attempt to justify the claim that the design should have been taken further and suggest the developments, within the technology known at that time, that could have been made

Firstly we have to ponder why is it that a rush-job fighter, designed and built in 65 days could be faster than the Hurricane and not much slower than a Spitfire while dragging around a greater load of fuel, ammunition and with undercarriage legs and having a pair of wheels sticking out under it.

It may or may not be coincidence that the fastest planes of the early WWII period were The Spitfire, lots of time was spent developing flush riveted finish in critical areas; the North American Mustang with very close fitting and carefully sealed joints in its aluminium covering, the later Vought Corsair with a smooth rivet-free spot welded skin and, of course, the Mosquito, another plywood clad, doped fabric covered wooden plane, known now as the ‘Wooden Wonder’.

From these examples it is clear that the surface finish is the common factor and it is that clean smooth blemish-free feature of doped fabric covered plywood that gave the M20 a head start in the quest for speed.

It can be seen that dome headed rivets are a handicap, energy has to be given to the air to move it around any bump or imperfection. They are the easiest and cheapest way to rivet, the flush rivet on the Spitfire requires the hole to be drilled and ‘countersunk’, machined or the metal skin punched downward to provide space in which the flat v shaped head sits, there remains a ring gap to disturb the air. It is an improvement but is not a complete solution. Spot welding of aluminium was a newly developed technique first used on the Corsair, it was not in general use.

It is so much easier to get a smooth finish in wood and fabric. Make a wooden frame and glue thin plywood sheet over it, at the Miles factory they held the thin plywood in place while the glue was setting by simply using staples, a development of the office stapler did the job just fine and saved a lot of time fiddling with pins, tacks and hammers. The plywood surface was covered in a fine cotton cloth called Madapollam and then doped, the dope tightens the weave of the cotton and provides a hard smooth surface. The weave of the cloth gives equal tensile strength in each direction, i.e. warp and weft of equal strength.

The four panel illustration show the various finishes on Hurricane, flush riveting, Mustang and Miles Master wings. The next photo, of a section of an aircraft flap, shows the complexity of ‘joggled’ joints needed to achieve a flush surface on an aluminium skinned aircraft.

Surface finish effect is demonstrated in an anecdote from a pilot of the later P47 ‘Jug’. In the final year of the war, with little fighter opposition over Germany, he flew his new aircraft unpainted except for its marking and found it to be 25mph faster that the camouflaged version. The RAF had depots where ‘rogue’ under-performing aircraft were tested and sorted out, over enthusiastic application of paint, deformation of surfaces by clumsy boots, pushing on places not designed to be pushed on were the usual causes and were easily remedied to give up to 20 mph improvement.

Dennis Bancroft, a designer employed by Miles, was of the opinion that anything would fly if you stuck a big enough engine on it and to an extent he’s quite right. He did appreciate though to get the best one had to be meticulous in the way the airflow around the aircraft was managed. In the last article I mentioned the wool tuft visualisation of airflow and the ease of which it could be done on wooden skinned surfaces, here then we have another advantage for the M20 development. Supermarine were pushing technology to make their thin wing for the Spitfire, special rivets had to be designed and used, Miles just carried on with what they were doing, and doing well.

Development

The first stage of development would be the fitting of exhaust stubs as on the Spitfire mentioned in the previous article, that would add five to seven miles per hour to the top speed. A manifold designed for night use is not the one to use in a day fighter, exhaust glare won’t be a problem for the pilot so there is no need for muffling which impedes the flow of the exhaust. That increase puts the M20 close to the Spitfire’s top speed.

Drag is the enemy of the aircraft designer and it comes in various forms. Surface finish is one, another is drag from the chin mounted radiator and the scoop to direct airflow through the heat exchanger matrix. Fitting four 20mm canon could free up some space in the wing to allow the fuel tank to be moved outboard to allow air intakes in the leading edge of the wing close to the fuselage resulting in an increased top speed and a bigger ‘punch’ from the canon.

The thin wing of the Spitfire meant that the installation of canon was complicated and constant jamming of the guns was a problem that delayed their introduction and caused many problems in service including loss of aircraft and, more importantly, pilots. It is likely that another five to ten mph could be gained by this modification.

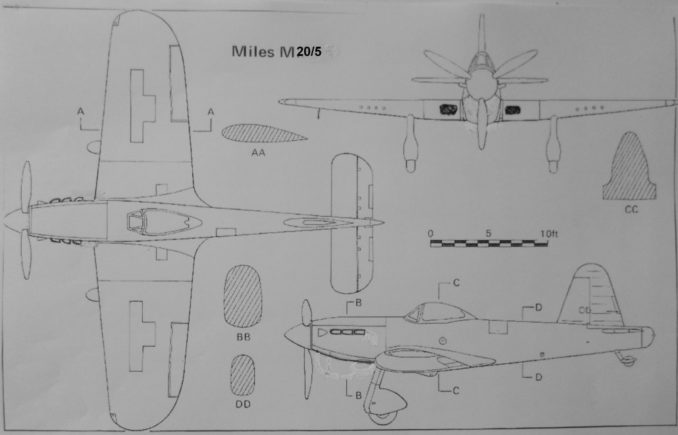

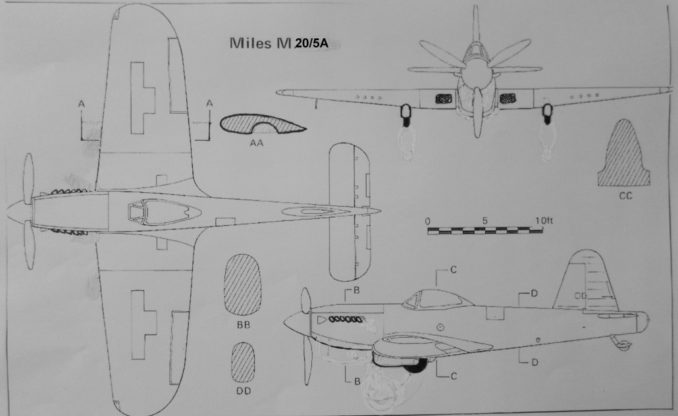

Some of the space freed up could be used to provide a recess for the undercarriage, or part of it, to fit into on retraction, the undercarriage would have cost maybe 30mph off the top speed, one 500 lb bomb under a Spitfire knocked 22mph from the speed.. The Spitfire did not have an ideal solution to retraction, there was a ‘draggy’ unfilled segment which remained uncovered, the black ‘half moons’ seen under the wing. The undercarriage fitted to the Master retracted rearwards and the wheel turned through ninety degrees to lie in the wing. Unless the wheel is fully enclosed by airtight covers there will be drag, a compromise could be reached by not rotating the wheel and allowing just a portion to retract into the wing. (a design solution used on the A10 warthog) There is an advantage with this system that in a landing with retracted wheels, after loss of hydraulics perhaps, there is a chance of far less damage being sustained than there would be with a ‘belly landing’.

All of these modifications could be done quickly and simply and would result in an aircraft maybe twenty to thirty mph faster than the Spitfire at that time. Development of the Spitfire was pretty much limited to fitting progressively more powerful engines leading up to the Griffon rather than the Spitfire; the same gains would be made by them being fitted to the M20 which would keep its lead. The M20, unlike the Spitfire, had a wing that could be developed for further speed gains.

The next avenue to explore would be to revert to the cranked wing of the Master-derived fighter, more expensive and complicated to make but it would give benefits of shorter undercarriage giving less drag if left as a fixed unit. With more powerful engines comes the need for bigger propellers to transmit the power to the air, a larger diameter prop means less ground clearance, longer, heavier, undercarriage legs or a cranked wing.

The use of water-cooled engine leads to the problem of the weight of the glycol/water coolant, tanks, pipework and radiators and the vulnerability of that system to loss of coolant from one stray bullet or piece of shrapnel.

My thoughts would go towards the use of an air cooled radial engine. As mentioned the water cooled Merlin is vulnerable to coolant loss and water cooling is a weight penalty as you have to cart the stuff around with you. With air cooling of the radial you don’t have to take the coolant with you, at operating heights you’ll be surrounded with the stuff, and it’s at minus 35 degrees centigrade or colder

As mentioned in the second part of this series Miles had been forced to modify the Master to Master II specification to use the Bristol Mercury radial engine; in that case the horse power was increased and there was a corresponding increase in speed although the frontal area of the aircraft was increased. What radials were available? Bristol were making the Hercules for their Beaufighter and other aircraft and produced it in ‘power egg’ form with engine bearers, ancillaries and cowling ready to bolt on to the front bulkhead. This engine was only three and a half inches larger diameter than the Mercury fitted to the Master but produced a great deal more power.

The first Hercules engines were available in 1939 as the 1,290 hp Hercules I, and it was soon improved to 1,375hp as the Hercules II. (Later, and I can’t find the date, the Hercules VI would produce 1,650 hp).Slightly less power but as no cooling system would be required it would be a good trade off. The engine was about 35” shorter than the Merlin so some space would be freed up in the fuselage for other things.

There is an additional advantage to the cranked wing design, for aerodynamic reasons the drag is less if the wing meets the fuselage on a radius, as shown in Fig. 4 below. There is an added benefit of not having to make ‘fillets’ to blend the wing to fuselage junction.

Another little bonus would be not being shot at by your own side for looking a bit like the German Fw190.

The space freed up in the fuselage would make me think of repositioning the cockpit or changing the posture of the pilot. It must have been the influence of the Victorian or Edwardian parents of the designers of the day that they had the pilot sitting up straight, shoulders back, as if at the dining table. This is about as bad as it get for coping with ‘g’ forces. German designers had latched on to this and designed a more laid back seating position; in this plane there would be space to bring the pilots legs further up and forward in the manner of sitting in a modern sports car. The pilot could be raised a little and the canopy heightened to give good all around view, the trade off would be a little more drag. The space under the seat could take fuel tanks displaced by the fitting of undercarriage wells and or intercooler heat exchangers for the superchargers

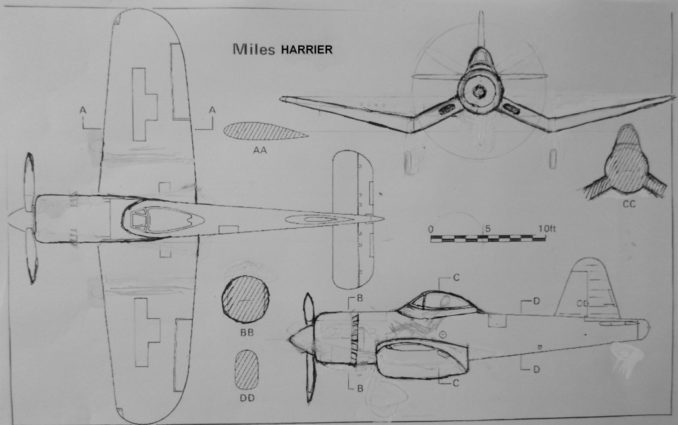

I mentioned the use of technology known at that time, only a year or so later in 1941 the effect of an all moving tail to solve the problem of the controls locking up in high speed dives was known to Miles. The concept arrived ‘fully formed’ in a specification in 1942 for a Miles research aircraft to investigate high speed transonic flight. As it was the M20 prototype had been cleared by the RAE to dive at 500 mph.

It is interesting to note that when these modifications are sketched out the result looks very similar to the Vought F4 Corsair. The staggered tailplane used by Miles is on the Corsair and the undercarriage retracts rearwards with the wheel rotating to lie flat in the rear of the wing as on the Master which surely would have been used on this Miles fighter, the bubble canopy too.

A canon equipped fighter, a rugged ‘wooden Corsair’, faster than a Spitfire, able to range far and wide and with a ‘flying tail’ allowing it to perform screaming 600mph plus dives would have been quite something.

Miles named many of their aircraft after British hawks, the name of one type of hawk was never used, so why not the Miles ‘Harrier’?

For a lot less money and a lot less production time, a chance lost.

Postscript

The Miles Aircraft Company was among the first to investigate the use of composite materials, that is fibre embedded in a resin, to make moulded parts. Some components of the Master were made that way, wing tips, fairing pieces etc. It is interesting to note that wood, a material the Miles persevered with when others were rushing to use metal, is a natural composite material in which fibres of cellulose which are strong in tension are embedded in a matrix of a ‘resin’, lignin, that resists compression. When the aircraft manufacturing business failed in the late forties Miles went on to form a company to take the composite materials idea further by making parts from fibreglass. Those of you up to date in aircraft design will note that metal isn’t the material of choice now, most designers choose composites, fibres strong in tension in a resin that withstands compression.

Miles Aircraft were ahead of the game in so many ways, it’s a pity that research and development funds, and aircraft orders, were not directed their way instead of funding dead ends like Spitfire development.

Anyone interested in the Miles Aircraft story should try to get to the little Museum of Berkshire Aviation hidden away at Mohawk Way (off The Bader Way), Woodley, Reading, Berkshire, RG5 4UE, It’s a good half day out. There is a small shop, cafe and seating area selling very good value drinks and cakes, there are friendly volunteer staff some of them are very well versed in the history of aircraft. It’s a large shed stuffed full of interesting things, anyone who might get bored can go and wander around the large Sandford Mill Copse Nature Reserve that adjoins the museum site.

© GrumpyAngler 2020

Audio file